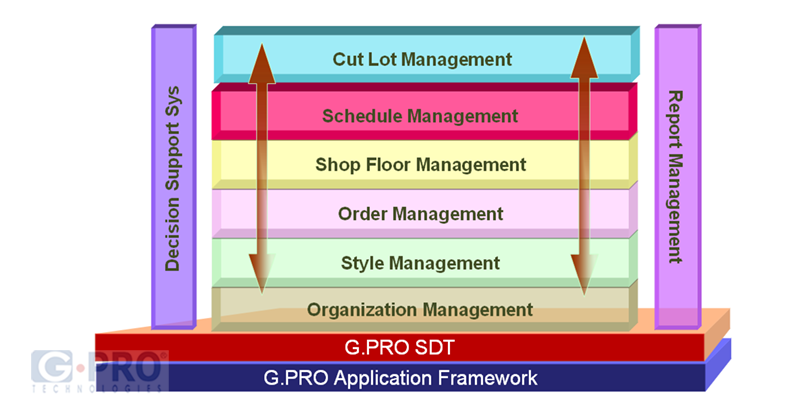

SDT is a dynamic RFID driven production tracking and management solution that works the way your apparel factory works, easily integrating into your existing infrastructure.

Merchandizers – In SDT, merchandizers add upcoming manufacturing orders from buyers with color, size, and quantity specifications into SDT’s rich order management interface. Merchandizers can split larger orders into smaller batches or search for previously completed orders from the same buyer or style.

Cutting/ Marker Design – With marker specifications, and cutlots finalized, cutting departments can specify rapidly the cutlots required and markers. Once the number individual bundle units are identified, employees can initialize hundreds of tags a minute with GPRO’s incredibly fast, tag-encoding Initializing Machines.

Production supervisors – Using SDT’s intuitive reporting and rich charting viewpoints, line supervisors and industrial engineers use this intelligence to drive line adjustments to free potential bottlenecks on production lines. Because you have a live updated view of the floor, fed to your monitoring workstations – SDT enables rapid adjustments and incredibly faster turn arounds.

Sewers – At the start of a shift, sewers log in at assigned sewing stations with GPRO’s RFID SmartTerms which reads their Employee ID cards. Garments are embedded with GPRO’s passive 13.56MHz RFID SmartTag. During the sewing process, workers use the GPRO RFID SmartTerm to read each tagged item or bundle and record the number of pieces they sew. Then, at the click of a button, employees can check their progress, and receive a summary of their total production quantity, efficiency and earnings in a particular shift.

- Eliminate manual work and minimize administrative costs.

- Reduce development and maintenance costs.

- Provide rapid, real-time information.

- Maximize customer and staff satisfaction.

- Increase productivity and accelerate time-to-market.

- Enable you to maintain optimal inventory levels and utilization of resources.

- Ensure information is accurate, relevant and up-to-date.

- Provide valuable management information.

See how others use it

The Hong Kong knitwear company has installed RFID interrogators at 8,000 sewing stations in three of its plants, so that it can record the number of garments made by each worker. See More

.…

tnx for info!!…